License #7018514

License #7018514

PLC Programming & Automation

Development and implementation of PLC-based automation systems for machinery and production lines. Engineering supervision and real-time monitoring to ensure seamless process control and operational reliability. Integration of HMI panels and custom software to optimize efficiency, accuracy, and scalability of industrial operations.

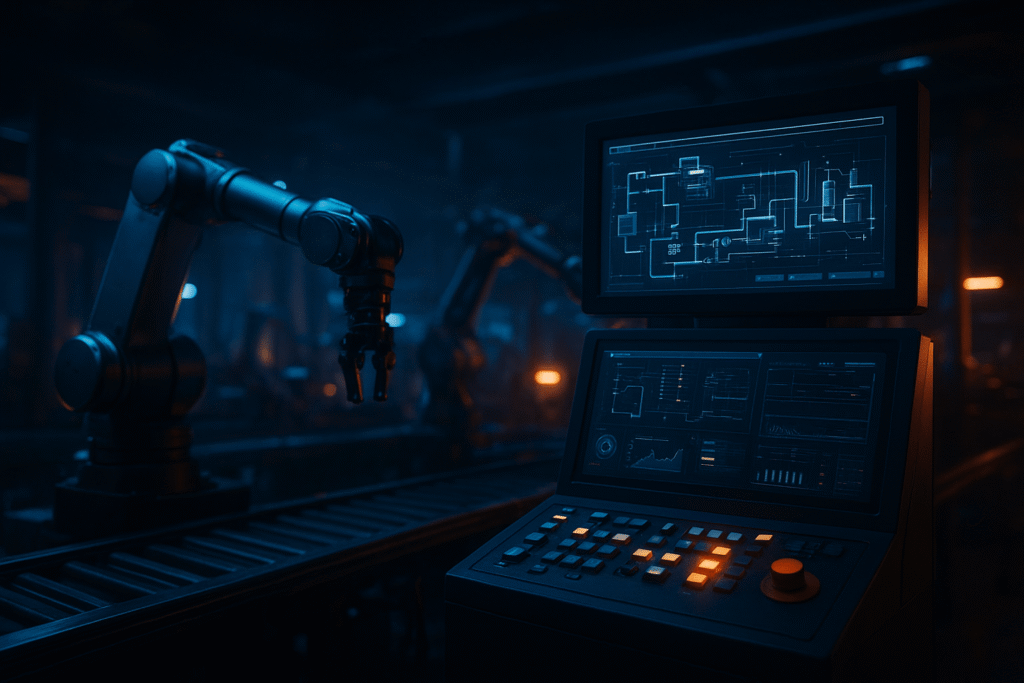

Industrial Automation Systems

Design and implementation of automated production lines with advanced robotics, sensors, and process monitoring tools. Integration of SCADA and PLC systems to ensure precise control, efficiency, and real-time data visualization. Optimization of energy usage and reduction of human error through smart industrial solutions.

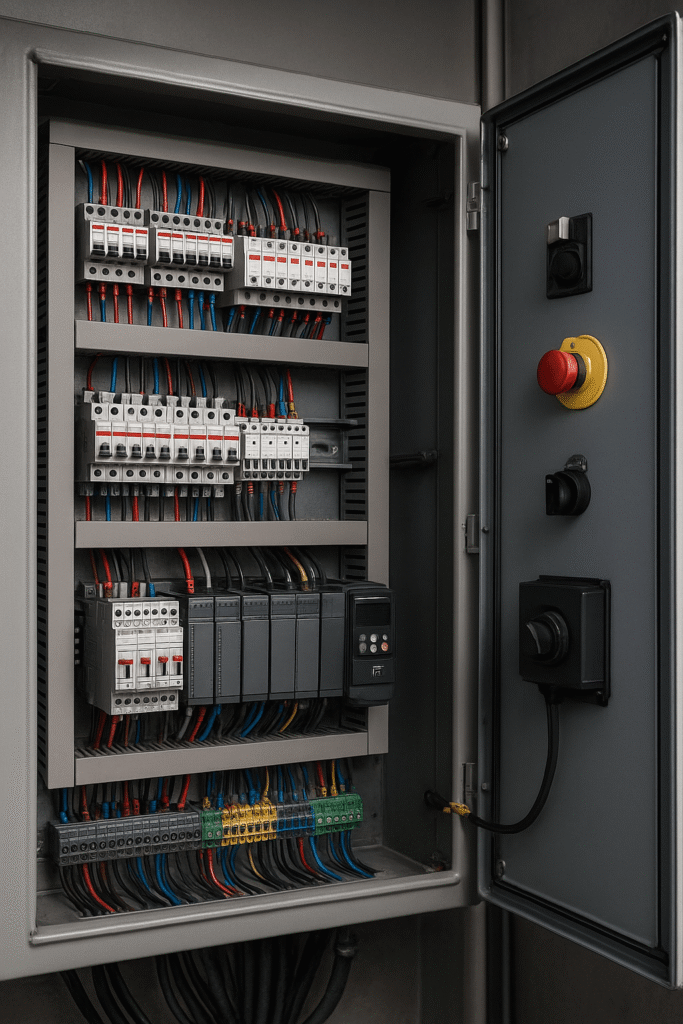

Electrical Panel Upgrades/ Modifications

"Upgrading and modifying electrical panels to enhance performance, ensure reliability, and meet specific industrial requirements."

ndustrial, Commercial & Residential Electrical Installations

"Providing safe and reliable electrical installations for industrial, commercial, and residential projects."

Troubleshooting & Root Cause Analysis

Specialized troubleshooting of electrical and automation systems, along with root cause analysis to prevent recurring failures.

Step 2: Solution Planning – Tailored to Your Vision

From these insights, our team outlines a preliminary concept for your custom equipment or automation system. This stage may include feasibility assessments, draft layouts, and suggested features designed to match your goals.

Step 4: Fabrication & Assembly – Precision and Quality First

After concept approval, production begins. Every unit is carefully manufactured and assembled with strict quality assurance and compliance to industry standards, ensuring a reliable, high-performance system.

Step 6: Training & Ongoing Support – Building Long-Term Value

We provide hands-on training so your team feels confident operating and maintaining the system. Beyond installation, our technical support and maintenance services are always available to keep your investment running strong.

Step 1: Discovery Session – Identifying Your Priorities

We begin with an in-depth discussion to learn about your business, challenges, and expectations. Together, we review your automation objectives and explore areas where improvements can bring real value.

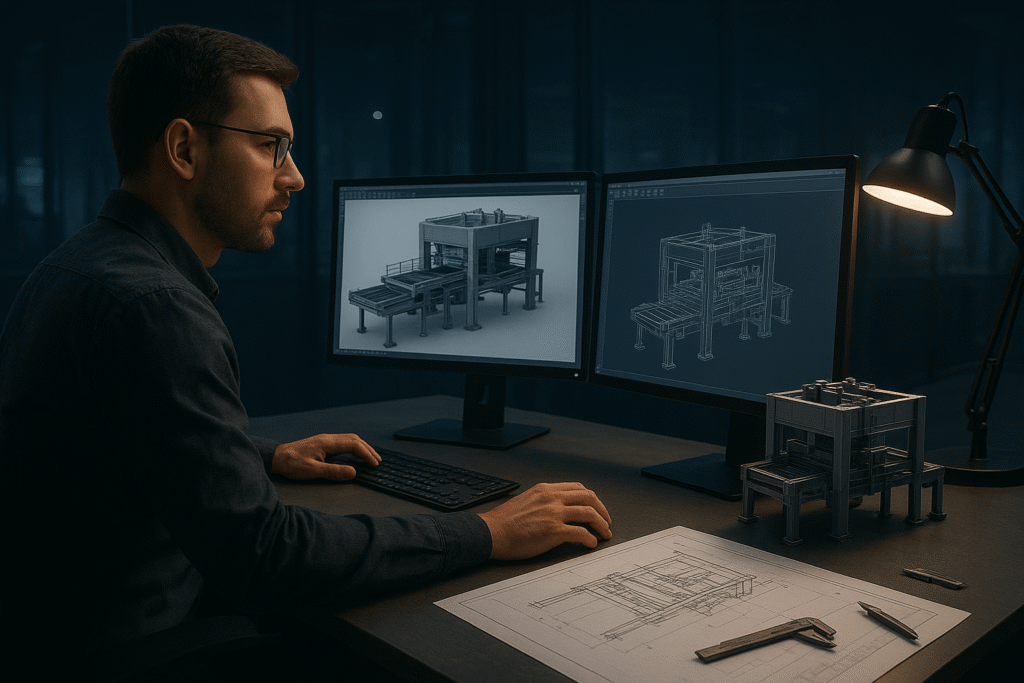

Step 3: Design & Engineering – Transforming Ideas into Reality

Our engineers turn the initial plan into detailed 3D CAD models and technical documentation. We run simulations, select the right materials, and carry out design validations to guarantee functionality, durability, and efficiency.

Step 5: Deployment & Integration – Smooth Implementation

Our specialists install and integrate the solution within your existing processes. We handle setup, calibration, and performance testing to reduce downtime and secure seamless operation.